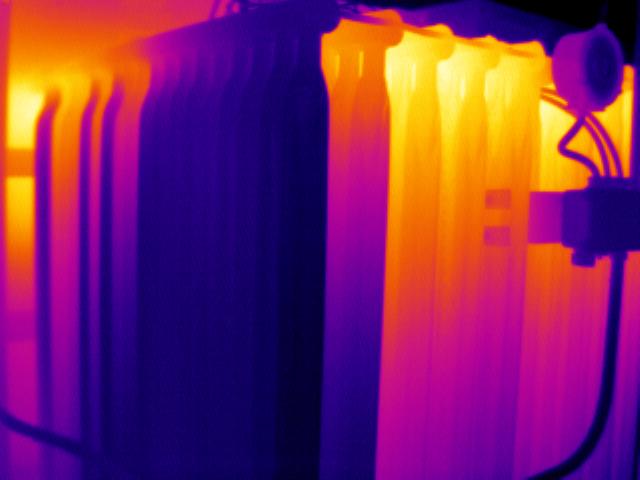

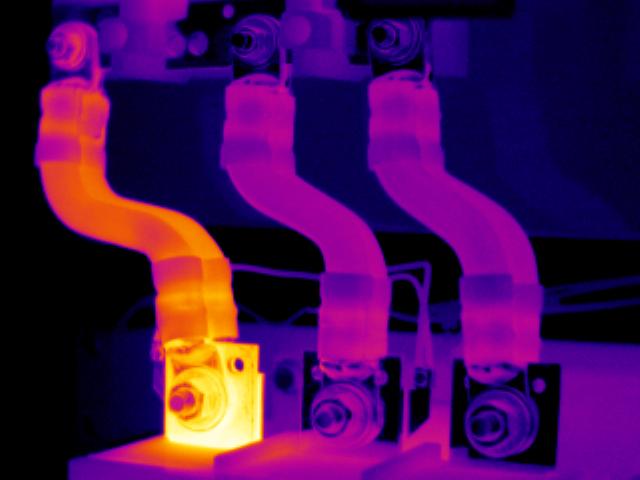

| Transformers | Bus Connections | CT's |

| Insulators | Breaker Panels | Capacitors |

| Cables | Switches | Control Systems |

| Plugs | Bushings | Fuses |

|

|

|

| IR windows are a tool that we can install aswell. These windows allow infrared cameras to view the equipment where as normal glass and plastic cannot. These make it safer for everyone involved and speed up the IR scanning time. |  |